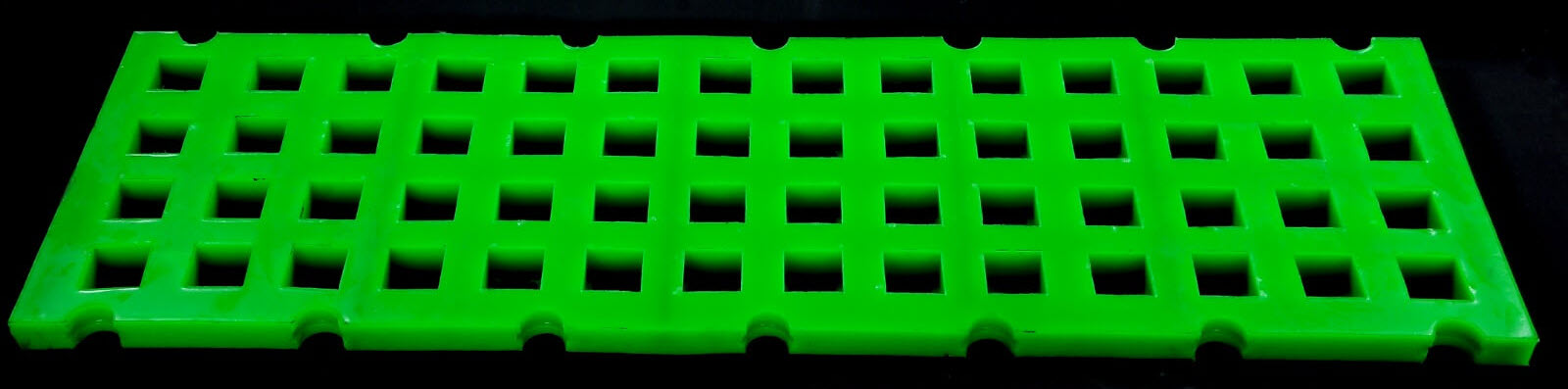

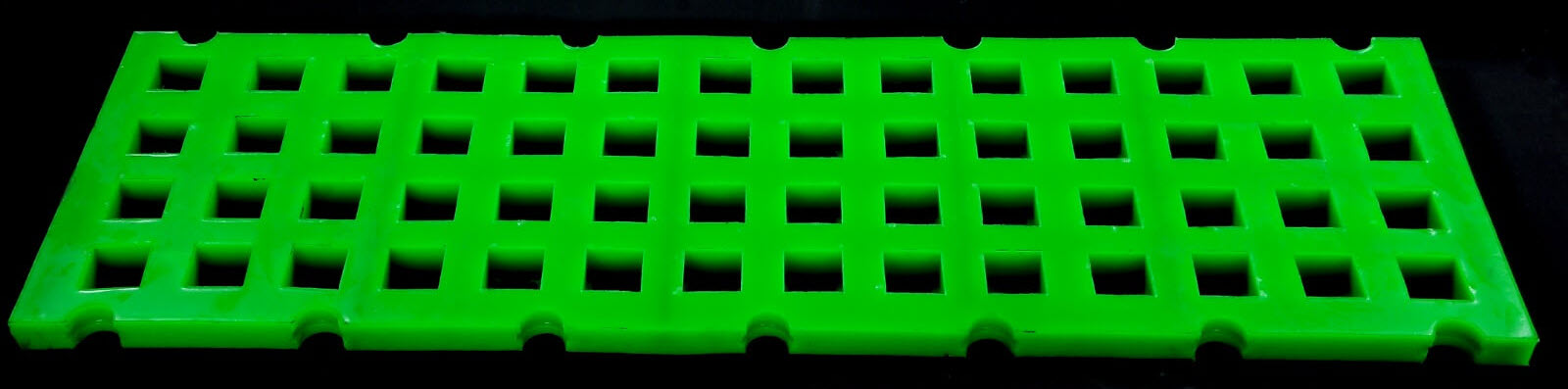

Modular Polyurethane Screen Panels

Kestasmak offers a full range of polyurethane products to screen your most difficult materials. These high-quality products offer long life in both wet and dry applications. Our products provide efficient screening of materials in many industrial applications such as de-watering, mining, sand, stone, gravel, and many others.

Features

• Superior abrasion and wear resistance

• Resilience and tapered openings reduce plugging and blinding

• Significant noise reduction

• Lightweight and easy to change out

• Wide array of openings and sizes

• Available in maximum open area design

Polyurethane Screens are used in the construction and cement industries as well as in the separation of minerals and ores such as coal, chrome, copper. Today, polyurethane sieves are preferred in many large and small-scale facilities due to the reduction of labor time and the ability to obtain the desired product from the same sieve for a long time.

During the assembly of Polyurethane Screen Panels, polyurethane wick is passed on the printing plates in the sieve frame. Thus, the screens are prevented from being cut and damaged suddenly from the bottom due to vibration. Polyurethane wicks are a kind of outfit of the screen frame printing plates and extend the wear life. The blades or profile wedges used in the assembly of plug-in module screens are coated with polyurethane to increase the wear time and prevent rusting.

Polyurethane Screen Panel Benefits

There are many benefits involved in using a polyurethane modular screening system which include the following:

- Easy changeover to maximise wear life and provide a more economical solution.

- High density precision injection moulded Polyurethane screening module.

- Modules available in: flat, inclined, with deflectors or weirs.

- Can be staggered on sub frame or supports for better screening.

- The support system used is firmly connected to the screen frame.

- Specifically designed for all mining and quarry industries.

Polyurethane Screen Panel and Applications

- Coal

- Sand & Gravel

- Media recovery

- Petrochemical

- Sludge Dewatering

- Irrigation Diversions

- Hydroelectric Diversions

- Petroleum Refining

- Architectural

- Pulp and paper

- Row water intakes

- Brewery Filtration

- Iron ore

- Coke

- Dredge dewatering

- Food processing

- Biological preservation

- Gold refining

- Municipal water intake

- Lakes, river, streams

- Crushed stone

- Potash

- Phosphate

- Cupper

- Recycle materials

- Fertilizers

- Wood chips

- Shale

- Metallic and Non-metallic materials

Polyurethane Screen Panel Apertures

| 0.15x11 |

15.5x9 |

7x7 |

28x28 |

| 0.25x11 |

1,8x11 |

8x8 |

30x30 |

| 0,35x11 |

2x2 |

9x9 |

32x32 |

| 0,50x11 |

2,5x2,5 |

10x10 |

35x35 |

| 0,53x11 |

3x3 |

12,5x12,5 |

40x40 |

| 0,75x11 |

3,5x3,5 |

15x15 |

45x45 |

| 0,85x11 |

4x4 |

18x18 |

50x50 |

| 1x1 |

4,5x4,5 |

20x20 |

60x80 |

| 1x9 |

5x5 |

22x22 |

80x80 |

| 1,5x1,5 |

5x5 |

25x25 |

90x90 |

SETAŞ GROUP

Modular Polyurethane Screen Panels

SETAŞ GROUP is a company that has proven its experience and success in the sector with the concepts of "quality, service and sustainability" with its flawless service approach since its establishment with the brand KESTAŞMAK. We will also offer you suitable solutions for your product requests.

As KESTAŞMAK, our goals are; to be a dynamic solution partner that develops innovative products and services, adding value to the industry and its stakeholders with the understanding of "ensuring the continuity of quality" and "keeping our customers at the center of all our processes, meeting their demands on time and with high quality".

SETAŞ GROUP, which always aims at customer satisfaction. You can reach us by calling our call center at

+90 (535) 047 1230

and get detailed information and offers.